Mines, mining and quarrying

Folder: Mining and quarrying

Autumn Q-pit

| |

|

A good example of a Q-pit, enhanced by autumn colours, Ecclesall Woods, Sheffield, England.

There are lots of Q-pits in Ecclesall Woods. The name derives from their shape in plan view. They are the remains of hearths used for producing 'white coal' - timber cut from coppiced trees which was heated to remove moisture. The white coal was then used for smelting lead ore from the Peak District. The Q-pits probably date from late-16th to mid-18th century.

Q-Pit in Ecclesall Woods

| |

|

This picture shows the remains of a Q-pit, (shaped like a 'Q' in plan view). There are lots of these in Ecclesall Woods in Sheffield and are the remains of hearths used for producing 'white coal' - timber cut from coppiced trees which was heated to remove moisture. The white coal was then used for smelting lead ore from the Peak District. The Q-pits probably date from late-16th to mid-18th century.

Woodhouse Rock

| |

|

Originally posted for the Sheffield Guesswhere Group.

This is the excavation for what is now the A57 dual carriageway Beighton bypass, south-east Sheffield. The rock face in the picture is made of well-jointed Woodhouse Rock, a sandstone unit in the Coal Measures (upper Carboniferous).

See where this picture was taken. [?]

Lair of the Soup Dragon

| |

|

Actually it's not tomato soup, but an ochrous minewater discharge from a collapsed, abandoned mineshaft in Ecclesall Woods next to the Limb Brook. The shaft forms part of the long abandoned Dore Colliery and dates from the latter part of the 19th century. The steel plate in the lower right is part of a V-notch weir used to measure the water flow rate. The water temperature here is about 12-13 C all year round due to the geothermal heating effect of the old abandoned coal mine workings that the water has flowed through before emerging from the top of this old shaft. The water is also fairly acid - pH about 5.5.

Orgreave S24's washout (3 of 3)

| |

|

This short sequence of three photographs is a rare chance to see how adverse geological conditions affected a (relatively) modern longwall face. They were taken on 2nd May 1980 at Orgreave Colliery, near Sheffield, South Yorkshire.

Please note that I did not take these photographs. They were taken by my colleague Jim Batty who was the NCB area photographer for South Yorkshire. I have used these on many an occasion to illustrate geology lectures and I am most grateful to him.

Photo 3: A closer view showing the small drilling machine boring the holes for shot firing. You can see previously drilled holes ready to be loaded with explosives.

This sort of situation caused extensive delays to production, and the difficult and, at times, unstable, roof conditions added to the risk of accident and injury on the face, although fortunately as far as I know, there were no serious incidents on this face (a wonder).

This whole washout area was around 20 - 30 metres wide from one side to the other, on a coal face that was about 180 metres wide. Eventually the washout sandstone lifted clear of the coal and production was able to be resumed relatively normally, although there were still roof control problems on this face for much of its life.

It was these sorts of conditions coupled with the fact that there was nowhere else left to work underground that led to the inevitable closure of Orgreave the following year.

Orgreave S24's washout (2 of 3)

| |

|

This short sequence of three photographs is a rare chance to see how adverse geological conditions affected a (relatively) modern longwall face. They were taken on 2nd May 1980 at Orgreave Colliery, near Sheffield, South Yorkshire.

Please note that I did not take these photographs. They were taken by my colleague Jim Batty who was the NCB area photographer for South Yorkshire. I have used these on many an occasion to illustrate geology lectures and I am most grateful to him.

Photo 2: A view looking along Orgreave S24's face in the Swallow Wood seam. The coal seam which was on the right has now been replaced by "washout" sandstone (light grey in colour). This is much too hard and strong for the normal coal cutting machine to cut through, and there would in any case have been the risk of hot frictional sparking causing ignition of any methane that might be present.

Instead, the sandstone has to be bored and broken down by firing with permitted explosives. That is what the men in the distance are doing. Previously fired-down sandstone is visible to the right of centre and the whole situation resembles an underground stone quarry rather than a proper longwall coal face.

Orgreave S24's washout (1 of 3)

| |

|

This short sequence of three photographs is a rare chance to see how adverse geological conditions affected a (relatively) modern longwall face. They were taken on 2nd May 1980 at Orgreave Colliery, near Sheffield, South Yorkshire.

Please note that I did not take these photographs. They were taken by my colleague Jim Batty who was the NCB area photographer for South Yorkshire. I have used these on many an occasion to illustrate geology lectures and I am most grateful to him.

Photo 1: A view looking along Orgreave S24's face in the Swallow Wood seam. The coal seam is on the right, the banks of hydraulic powered roof supports are on the left. The normal travelling way (a crawl!) is beneath this canopy of supports. In the centre leading away into the distance is the armoured steel conveyor (the 'panzer'). You can also see the sprocket chain that coal cutting machine (not visible here) used to haul itself along the top of the conveyor.

This particular coal face operated in the year before the mine closed, and it was beset with geological difficulties, which were suspected in advance, and that's why this particular patch of coal was one of the very last to be worked.

The main problem was the irregular, undulating sandstone roof. In essence, the coal was worked beneath a complex 'fossil' river channel system, where sand originally deposited by the rivers fills in the channels and eventually gets turned into sandstone. In this photo the sandstone is pale grey and sits fairly evenly on top of the coal. But it is already breaking into large lumps and falling out prematurely. Further on, in photos 2 and 3, the river has cut down more deeply and eroded away the vegetation that was to eventually become coal, causing a 'washout'.

It was part of my job to map these channel features and to try to predict what they would do next. So I spent a lot of time on this particular face. I remember it very well indeed.

Blast-off!

| |

|

Drilling an angled borehole prospecting for shallow coal at Tinsley, Sheffield, around 1989 on the abandoned steel works site for the proposed Sheffield airport. The dust cloud is due to the compressed air flush removing the cuttings from the borehole at high speed.

Taken with a Zenit 'E' on Kodacolor film

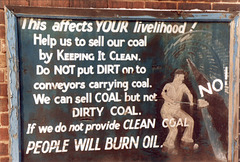

Dire Warning at Orgreave!

| |

|

This warning poster was painted on a wooden panel and fixed to the side of the upcast shaft next to the air lock doors. It was therefore visible to all mine workers as they entered the shaft just prior to going underground.

This photo was taken around 1977 and the poster had been there for many years previously. When the colliery closed in 1981 I wanted to salvage it, but by then it had deteriorated too much and could not have been removed without irreparable damage.

Taken with a Zenit 'E' on Kodacolor film

Winter scene at Orgreave

| |

|

View of Orgreave No.1 (downcast) shaft on a winter's day in 1977.

Taken with a Zenit 'E' on Kodacolor film. Changed to B&W in Photoshop.

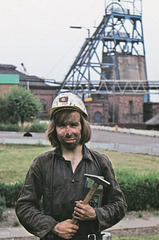

The young Earthwatcher

| |

|

|

Me at Orgreave in 1976!

One of the colliery surveyors took this photo just after I'd come out of the pit.

My Grandmother who lived all her life in the south of England could not believe that I worked in a job where I got dirty with coal dust, so this was taken just to show her.

Orgreave Colliery was located on the east side of Sheffield, between Handsworth and Treeton. It was opened in 1851 and closed due to exhaustion in 1981 - 130 years of continuous coal production.

Taken with a Zenit 'E' on Agfa CT-18 transparency film

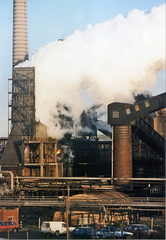

Orgeave Coke Ovens 1988

| |

|

Coal from Orgreave Colliery was taken directly into the adjacent British Steel coke ovens to make metallurgical coke for the steel industry. There was also an extensive coal by-products chemical works at the same site.

When the wind was in an unfavourable direction, it blew the fumes from the coke ovens straight over the colliery downcast shaft where the smell was quickly spread all round the mine workings underground.

Orgreave Colliery ceased production in 1981, but coal from nearby Treeton colliery was transported by conveyor to the coke ovens.

Treeton Colliery October 1977

| |

|

As well as a general view of the colliery looking south, this shot shows the portal area of the Surface Drift under construction. This near-surface portion is now partly covered in colliery spoil and will eventually be landscaped.

This area is now a posh housing estate.

Treeton No.1 Shaft headgear

| |

|

The steel headframe and pulley wheels over the No.1 (downcast) shaft. This shaft was mostly used for coal winding and the open lattice construction of the headframe allowed fresh air to enter the mine workings.

Treeton Surface Drift construction 16 June 1977

| |

|

|

This shot shows the portal area of the Surface Drift under construction in 1977. The steel arch girders are being encased in concrete. Eventually this near-surface portion will be covered in colliery spoil and landscaped.

Treeton Surface Drift construction 16 June 1977

| |

|

This shot shows the portal area of the Surface Drift under construction. The steel arch girders are being encased in concrete. Eventually this near-surface portion will be covered in colliery spoil and landscaped.

Treeton Surface Drift construction 16 June 1977

| |

|

This shot shows the portal area of the Surface Drift under construction. The steel arch girders are being encased in concrete. Eventually this near-surface portion will be covered in colliery spoil and landscaped.

Treeton Surface Drift 26 October 1977

| |

|

Here, the portal area is now completed and the main tunnelling work is well under way.

Jump to top

RSS feed- Latest items - Subscribe to the latest items added to this album

- ipernity © 2007-2024

- Help & Contact

|

Club news

|

About ipernity

|

History |

ipernity Club & Prices |

Guide of good conduct

Donate | Group guidelines | Privacy policy | Terms of use | Statutes | In memoria -

Facebook

Twitter