Two blue tits

Two blue tits

The missing link!

The missing link!

MBI5030-starter-board-01

MBI5030-starter-board-02

MBI5030-SB assembly 1

MBI5030-SB assembly 5

MBI5030-SB assembly 8

MBI5030-SB assembly 12

MBI5030-SB assembly 6

MBI5030-SB assembly 14

MBI5030-SB assembly 2

MBI5030-SB assembly 9

MBI5030-SB assembly 7

MBI5030-SB assembly 15

MBI5030-SB assembly 4

MBI5030-SB assembly 11

MBI5030-SB assembly 3

MBI5030-SB assembly 13

MBI5030-SB assembly 10

MBI5030-SB assembly 16

Akafugu LED candle

A blue tit

LED ring light - back

Two mirrors are needed

LED ring light - front

Sugru 'gasket'

Sugru 'gasket'

Multiple reflections

Multiple reflectoins

Multiple reflections

LED ring + Sugru

Multiple reflections

Almost successful

Is this real?

Pentax S5z LED ring

Pentax S5z LED ring

Pentax S5z LED ring

Pentax S5z LED ring

Pentax S5z LED ring

Pentax S5z LED ring

Pentax S5z LED ring

Pentax S5z LED ring

Pentax S5z LED ring

Keywords

Authorizations, license

-

Visible by: Everyone -

All rights reserved

-

179 visits

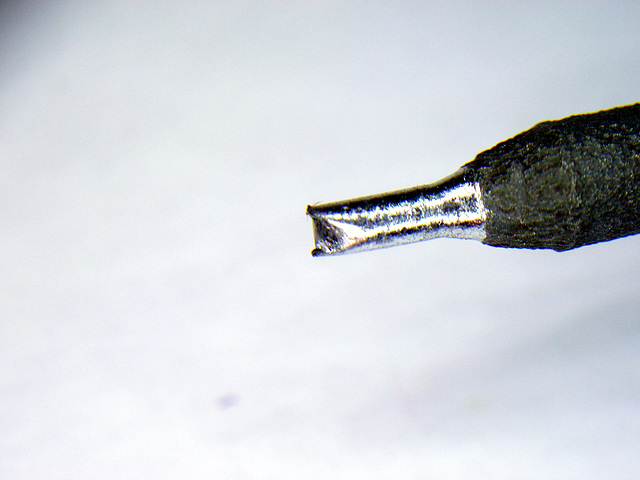

That tip has had it - Weller WMRP RT3

I've had difficulty soldering properly with well-established settings for quite some time now. I had to set the temperature to 400°C to get just decent operation. I measured the temperature as well and it was fine.

Looking at the tip closely revealed significant erosion, hence lack of physical contact with the PCB and miserable heat transfer.

For the time being I chose to grind the little peaks away, fully knowing that the plating will deteriorate even faster, but at least I can get stuff done for now. I'll need a replacement pretty soon.

After just 3 years of moderate usage, the plating is gone. I have a feeling most of the damage was caused by the brass shavings used to clean the tip.

Now I'll have to fork out 40 something to buy a new one, as the heating element is inseparably fused to the tip.

You cannot just replace the tip itself and keep the fully functional heater / sensor / pencil, you have to throw away perfectly good hardware, just because the tiny tip is EOL.

Looking at the tip closely revealed significant erosion, hence lack of physical contact with the PCB and miserable heat transfer.

For the time being I chose to grind the little peaks away, fully knowing that the plating will deteriorate even faster, but at least I can get stuff done for now. I'll need a replacement pretty soon.

After just 3 years of moderate usage, the plating is gone. I have a feeling most of the damage was caused by the brass shavings used to clean the tip.

Now I'll have to fork out 40 something to buy a new one, as the heating element is inseparably fused to the tip.

You cannot just replace the tip itself and keep the fully functional heater / sensor / pencil, you have to throw away perfectly good hardware, just because the tiny tip is EOL.

- Keyboard shortcuts:

Jump to top

RSS feed- Latest comments - Subscribe to the comment feeds of this photo

- ipernity © 2007-2025

- Help & Contact

|

Club news

|

About ipernity

|

History |

ipernity Club & Prices |

Guide of good conduct

Donate | Group guidelines | Privacy policy | Terms of use | Statutes | In memoria -

Facebook

X

Sign-in to write a comment.